Laser-based manufacturing systems

We design laser processes and post processing techniques. We also develop large-area laser markers, polymer laser welders and participate in the design and development of 3D printers. Our research and development finds application in CSIR laser-based services such as surface modification, product manufacturing and metal additive manufacturing.

Contact information:

Highlights

Our capabilities

Laser based manufacturing systems

Laser Refurbishment/Cladding

Laser Welding

Laser Shock Processing

Laser Based 3D Printing

Design and fabrication of integrated photonics product prototypes

Our facilities

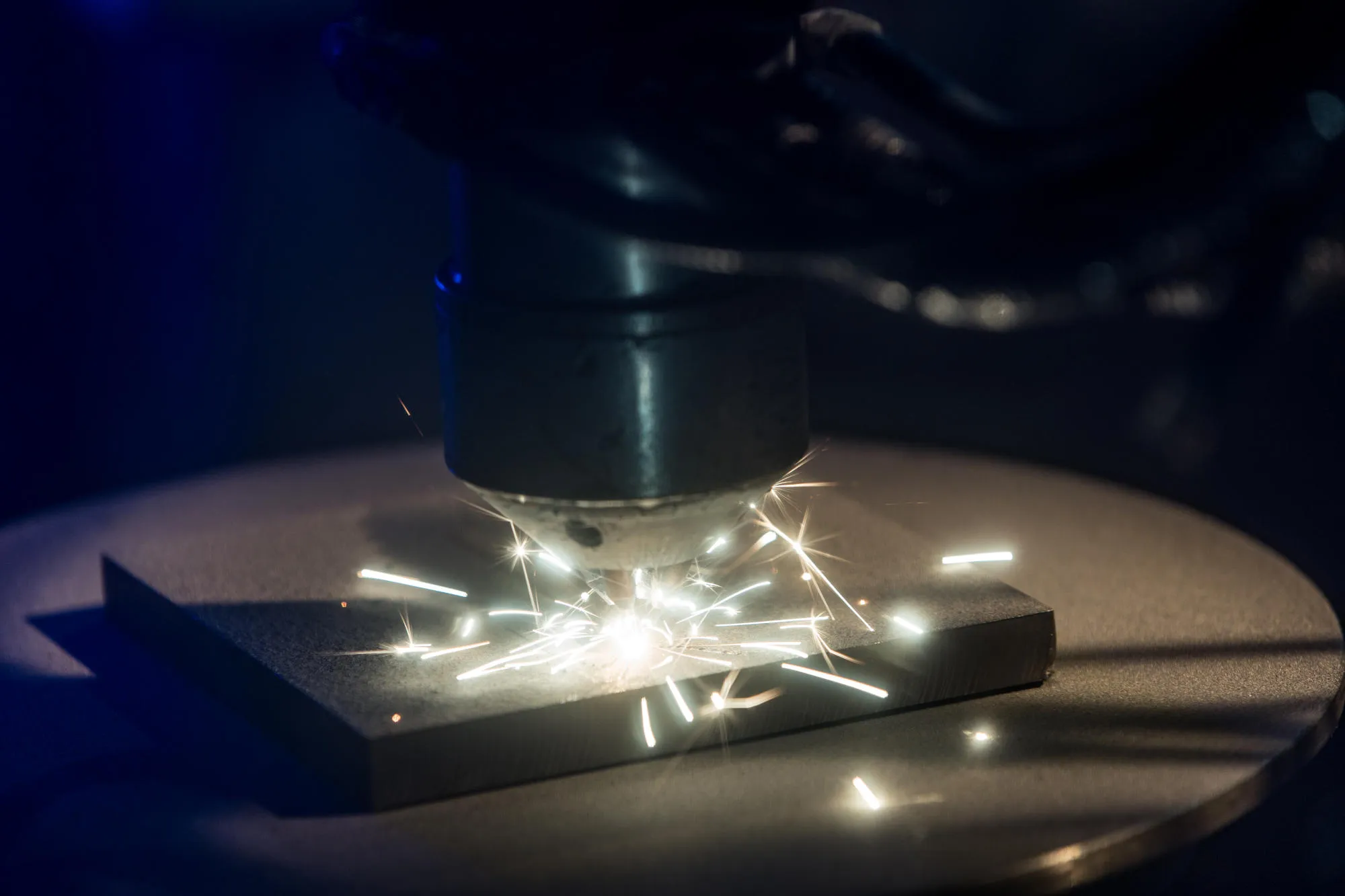

Hummingbird PBF Machine

The Hummingbird machine uses a multi-mode 5kW laser and a smaller 400mm diameter powder bed to develop process parameters and print smaller parts for materials other than Ti-6Al-4V like Aluminium and stainless steel alloys. These processes can also be transferred to the Aeroswift machine, should the business case for alternative large metal parts warrant it.

A second machine was also developed, named Hummingbird PBF Machine to:

- Develop processes and print parts in materials other than titanium at high laser powers.

- Do fundamental research on high-power selective laser sintering (SLS).

- Testing multimode laser technology to reduce the cost of high-power laser AM machines

Work with us

Link to - Collaborative Programme in Additive Manufacturing Link to - Laser Rental Pool Programme