What we do

What’s new?

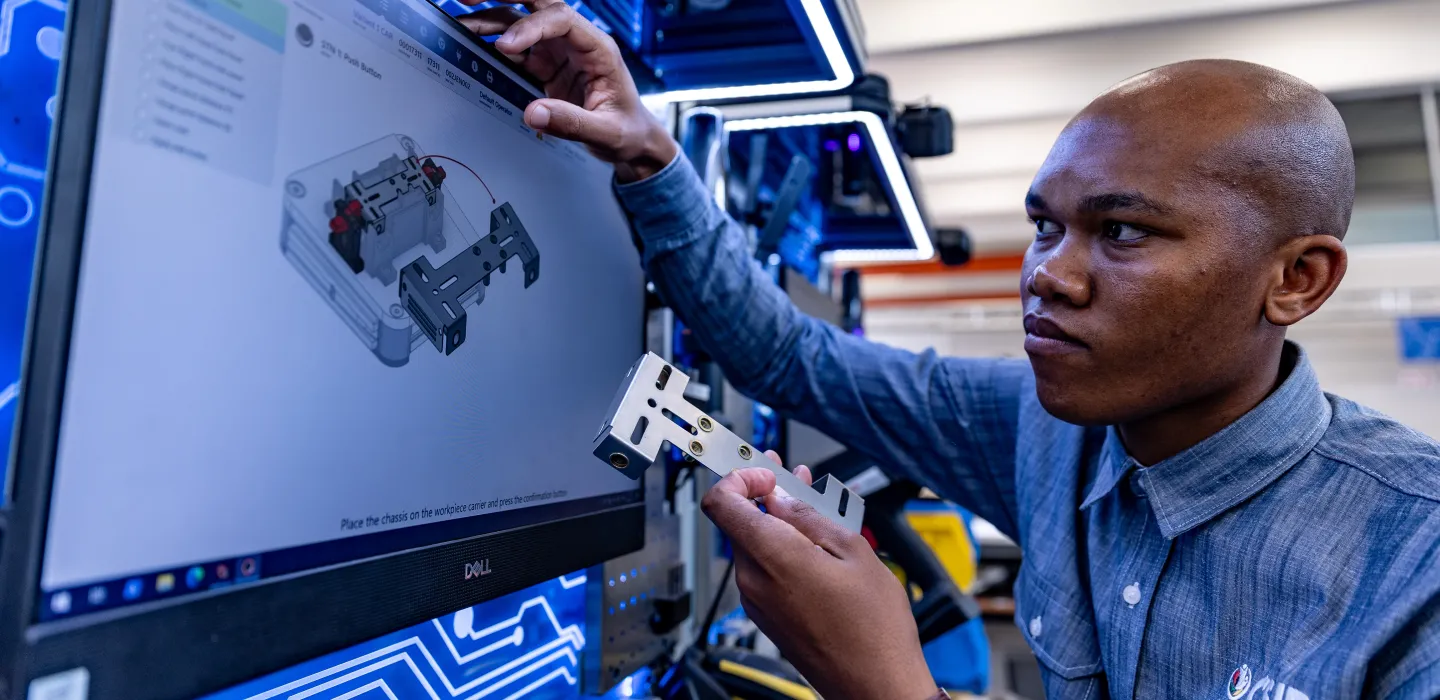

A manufacturing execution system to help small companies

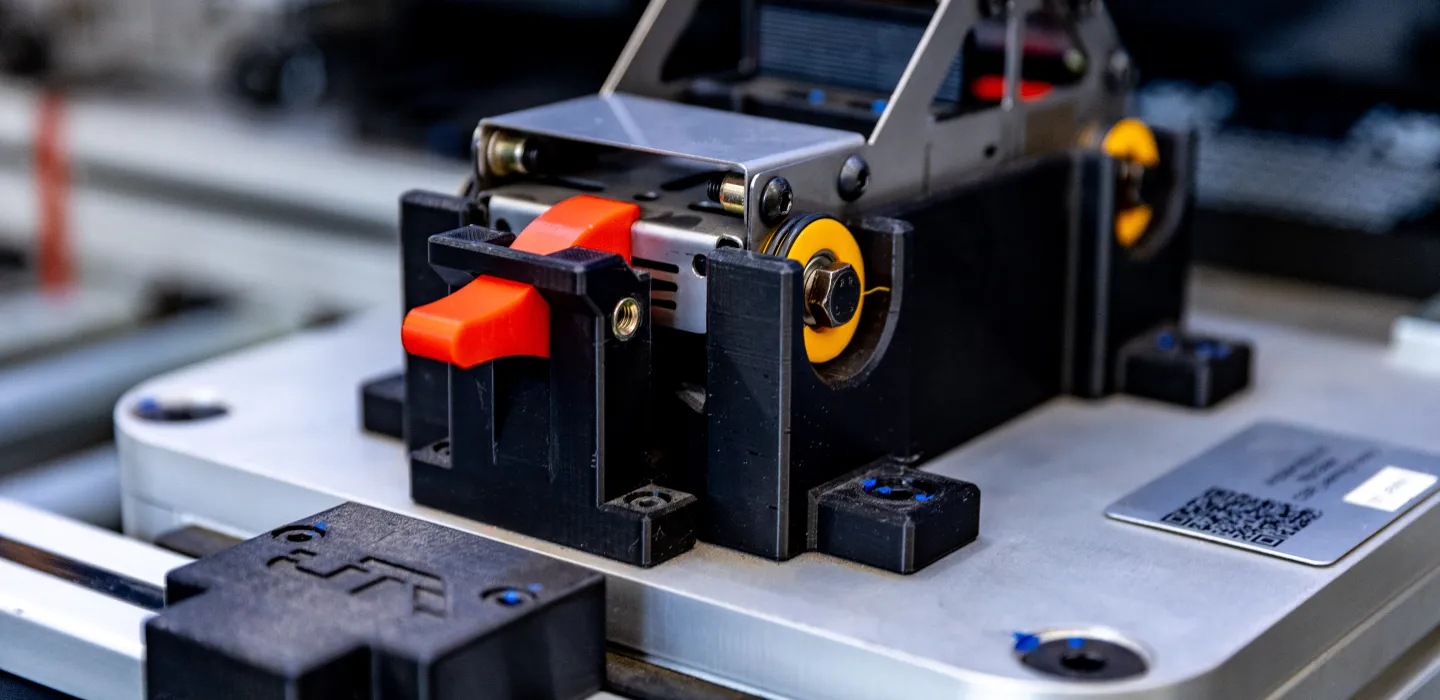

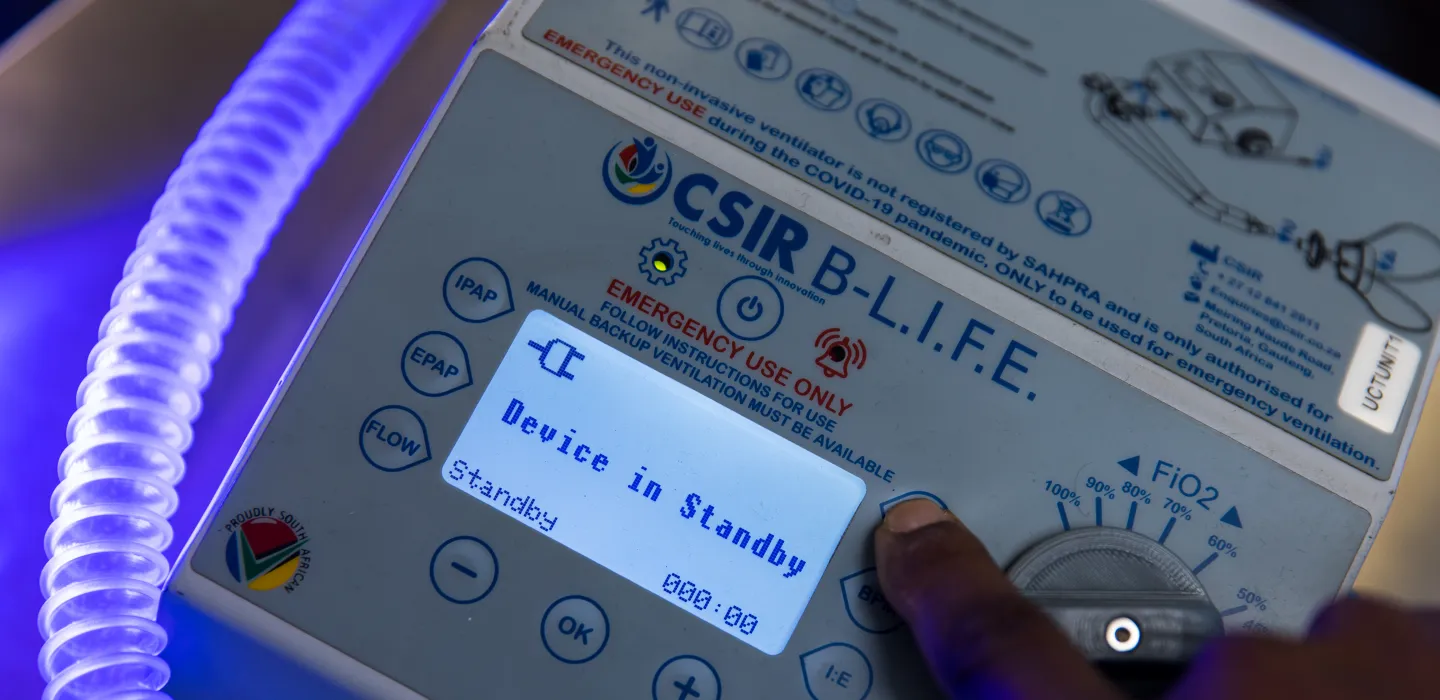

The CSIR has developed a manufacturing execution system to support SMMEs with their production process. The system is designed to oversee, manage and schedule manufacturing processes, operators and machinery. Monitoring functions include power usage of machinery with smart plugs or power meters, oversight of robotic arms, and quality control monitoring. Existing automated quality assessment systems can be integrated into the system, which was co-developed with MESA Africa to align with international standards.

Robotic vineyard inspection system

We developed a rugged robotic platform for mapping of plants and vineyards, and performing environmental monitoring. The software on board is customisable and uses infrared technology to assess canopy density and growth, evaluate soil conditions and measure crop temperatures.

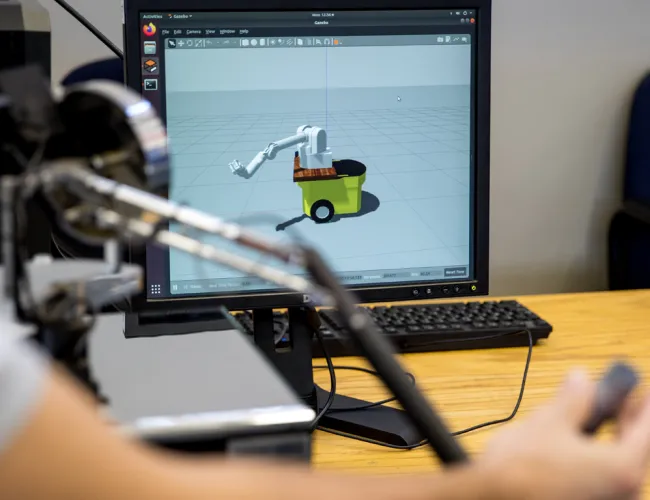

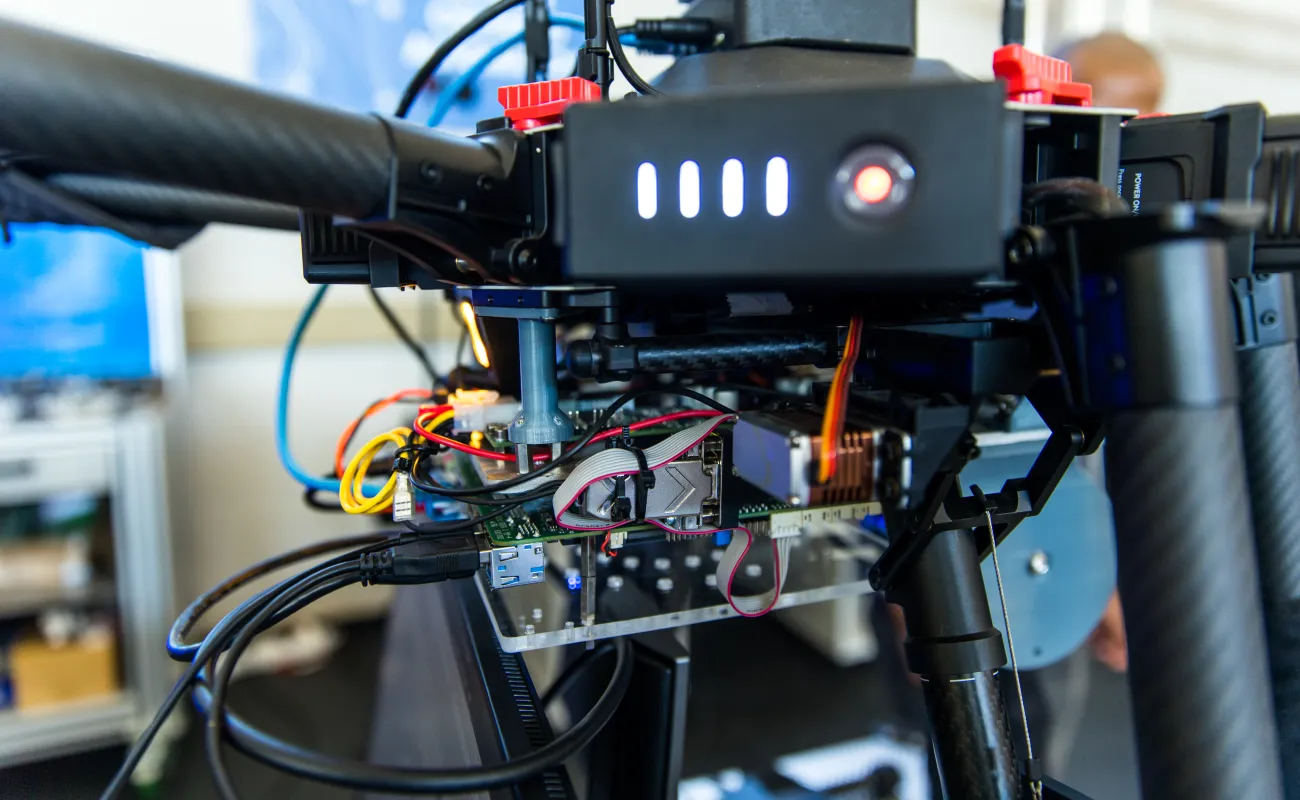

AeRoMAX robotic platform

In areas where GPS signals are unavailable, 3D mapping becomes essential. The AeRoMAX robotic platform is used for autonomous mapping and path planning. The sensor payload collects and analyses data that enable accurate and reliable mapping in challenging, closed environments such as mines.

Research

Contact information:

Our Facilities